InventivE X

Design Build

Explore some parts of an interesting story….

This castle is not a fairy tale. It’s the first permitted 3D-printed concrete structure in the U.S., born from a 2014 backyard experiment. What began as audacious ingenuity became the foundation for a global shift in construction, proving that monumental innovation starts with a single layer.

The material for this castle project was sourced from a local Home Depot in Minnesota. A decade later, this foundation-free structure remains as pristine as the day it was built—completely maintenance-free.

Redefining architectural boundaries, this castle structure showcases the unparalleled versatility of 3D concrete printing. Curves, arches, and intricate geometries flow seamlessly, proving that for a machine guided by code and creativity, complexity is merely mathematics in motion.

“We’ve been building with this technology since the late 2000s, with our first successful test in 2012. Since then, we’ve been continuously innovating, pushing the boundaries of this industry….”

Andrey rudhenko

Early on, we focused on maximizing design freedom in our projects. Architectural beauty has always been a core motivation in our adoption of 3D concrete printing.

We take pride in the consistency and quality of our materials. It’s not magic—it’s experience and dedication. Crafted on-site using locally sourced components, our approach ensures maximum flexibility and structural integrity, perfectly suited to the climate and culture of each location.

“The ability to effectively integrate the concrete 3D Printing technology with electrical, plumbing and other technical and architectural systems is crucial in achieving a successful 3DCP project”

Sebin Joseph

3D printing is only a part of the entire construction process we we take care of every other systems go into your home. Plumbing, electrical, HVAC etc are expertly integrated into the walls.

An interesting fact

See the first commercial 3D print in the world.

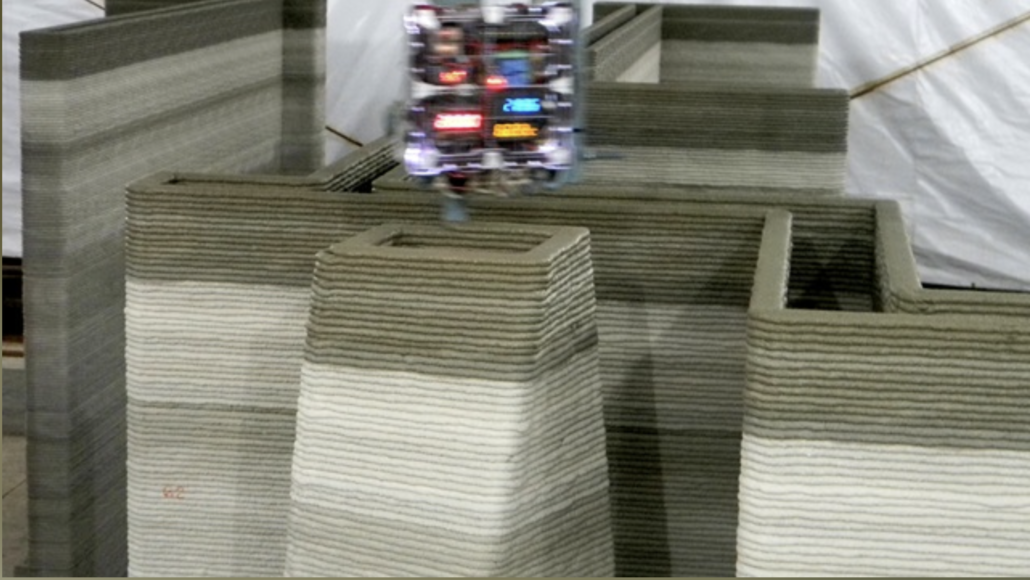

When you hire us, you’re getting the team that built the world’s first 3D-printed concrete hotel. This small hotel, completed in the Philippines in 2015, was a groundbreaking achievement—at a time when no building in the U.S. had yet adopted this technology. Even today, no hotel in the U.S. has been constructed using this method.

Over the years, this technology has evolved significantly. In 2015, the hotel had to be built under a temporary cover for protection against the elements. Today, we can construct with confidence, unaffected by minor weather changes.

Beyond the simplicity of hobbyist layers, this technology demands exacting precision, structural mastery, and engineering ingenuity—transforming raw material into enduring innovation, one monumental layer at a time.

A fusion of pioneering spirit and groundbreaking technology, where collaboration fuels innovation. Here, knowledge meets ambition, and every blueprint etches a legacy—transforming how we build, learn, and inspire together.

Another interesting fact

We built the first custom build home in the USA.

Yes there are families living in our homes. And they are happy about the product. See some moments from the first custom built 3D Printed home in America.

This 1,700 sq. ft. concrete home features 3 bedrooms and 2 bathrooms, designed with energy efficiency and modern style in mind. A family of five has been living comfortably in this high-performance home.

This home was 3D printed using materials sourced from local suppliers, featuring unique design elements such as curved walls, large open beams, and distinctive slands. Every detail was carefully crafted to meet the specific needs of the client, making this home truly one-of-a-kind.

It only took three people to print the entire home, and they’re still here to share the exciting story of how it all came together…

This project is a testament to our ability to work in any conditions. Whether it’s snowing, raining, or sweltering hot, we deliver—no problem.

It is built one layer at a time, all throughout the day..

Certain parts of the building were printed in pieces and later assembled to form the monolithic structure you see in the finished structure.

When we built it, this was the tallest single-story structure created using concrete 3D printing, standing at 14 feet. The design also includes a slanted roof to accommodate solar efficiency.